Dalian epidemic situation is on the hot search again, cold chain UV LED sterilization is imperative

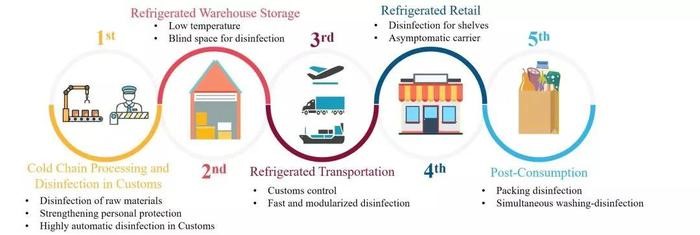

Recently, the Dalian epidemic situation has been frequently searched, and the increasing number of cases has attracted widespread attention. After tracing the source, it is mainly caused by the cold chain, and then people’s eyes are focused on the cold chain.

On December 7, related media reported that the team of Academician Ma Jun from the School of Environment of Harbin Institute of Technology published a view entitled "Challenges of Global Spread of New Coronavirus Cold Chain Logistics and Multi-level Green Barrier Epidemic Prevention and Control Countermeasures" in the journal Engineering of the Chinese Academy of Engineering. The article also proposes that compared with disinfectants, the green disinfection technology represented by ozone disinfection and ultraviolet disinfection has obvious advantages such as extremely low output of harmful disinfection by-products, low environmental residues, and high safety. It is recommended to be used in cold chain goods During the normalized disinfection stage, the use of green disinfection technology should be promoted.

UV disinfection mercury lamp VS UVC-LED

Indeed, as an indispensable part of people’s lives today, cold chain products are vital to both consumers and operators. If the new crown virus is allowed to wreak havoc in cold chain products, people’s safety of daily life cannot be obtained.

Ultraviolet disinfection is one of the green disinfection technologies, currently mainly in two forms: ultraviolet mercury lamps and UV LEDs. Because of its mature technology and low price, ultraviolet mercury lamps occupy the main market for high-power products such as water treatment, industrial sterilization, and hospital sterilization. However, the ultraviolet mercury lamp, as a disinfection solution that cannot be directly viewed, cannot irradiate organisms and contains mercury, undoubtedly has a greater risk, and it is also a technology that is being phased out in the market.

Compared with the ultraviolet mercury lamp, UVC-LED is a rapidly developing ultraviolet sterilization technology route in the market, and it is non-toxic. In the disinfection of cold chain food, UVC-LED can not only kill microorganisms such as coronavirus and bacteria on the surface of the food, but also maintain the fresh flavor of the food and extend the shelf life, which is very important for cold chain production.

Summary

From the point of view of advantages: UVC-LED in UV disinfection is used in the cold chain, non-toxic and environmentally friendly, small in size, longer life, lower energy consumption, lower heat radiation, in line with the production cost of enterprises and solves the consumer’s need for purple chemistry, etc. Other disinfection methods have caused concerns about the hygiene problems of toxicant residues.

From the point of view of application: cold chain products, as an indispensable part of people’s lives today, are vital to both consumers and operators. Ultraviolet UVC-LED can kill microorganisms such as coronaviruses and bacteria on the surface of food It can also maintain the fresh flavor of the food (note the dosage). For some products that need to be transported to other regions for sale, there is an extended shelf life, which is very important for cold chain production.

From a development point of view: With people’s requirements for the safety, environmental protection, compactness, high efficiency, low consumption, and no chemical residues of disinfection products, government policy support in many places, the industry’s own technology upgrades, and the safety and convenience of UVC-LEDs are increasing. The more consumers understand and accept, UVC-LED will be more common in the cold chain production and disinfection process. (However, it should be noted that due to power, WPE and cost reasons, UVC-LEDs are not as good as mercury lamps in some scenes for a long period of time. However, as the power of UVC-LEDs increases, the cost decreases, and the cold chain logistics is large. Scale use is worth looking forward to.)

If UVC-LED can be widely used in the cold chain production and disinfection link, cold chain product operators will not have to worry about slow sales, and the majority of seafood lovers can enjoy the food without worrying about food safety.

ShineOn is deeply engaged in healthy intelligent light source, providing the market with a full range of UV UVA, UVC, LED, IR LED VCSEL products and program services, with hundreds of high-quality partners in the domestic and foreign markets, to jointly promote the cause of light science and technology to create a healthy and intelligent life.

Post time: Dec-13-2021